Since 2020, Orion has been delivering buildings made with the Light Steel Framing or LSF process.

We are constantly following the technological evolutions in the field of construction in order to render the projects that have been entrusted to us, the most sustainable in the constructive and ecological sense. We are a pioneer in Switzerland in the use of LSF.

But what is light steel framing? Here we want to tell you about its history, the multiple benefits of this process, and how we make the most of it at Orion.

History and definition of light steel framing

A construction system born in the United States in the 1930s, Light Steel Framing is a system of lightweight steel structures. That is, a lightweight steel structure made of galvanized steel profiles that work together to support the construction.

Reinforced cement plates are directly fixed on the profiles of the structure.

This system allows the design of buildings with better technology, durability and eco-energy than in traditional construction (reinforced concrete, bricks…)

Already widely used in the US, Canada, Australia, South Africa and Japan, it is more recent in Europe.

The advantages of LSF

Light steel framing offers multiple advantages:

A strength-to-weight ratio that opens up other possibilities

The profiles are shaped from flat rolls of light steel (1 to 3 mm thick), as opposed to the heavy steel that makes up the skeleton of traditional buildings. Galvanized steel has an unmatched strength/weight balance compared to conventional structural designs.

The load-bearing performance of the LFS model is constant over time, unlike wood and concrete which can be easily weakened by natural elements (carbonation, termites, rot…)

With the same cross-section, LSF steel beams are much stronger than traditional beams. They allow larger reaches to be achieved. Fewer load-bearing walls and a notable reduction in the weight of the whole (thinner walls and shallower foundations). A 100 m2 LSF steel house will weigh about 10 tons compared to 60 tons for a 100 m2 brick house. Perfect resistance technique that allows a construction up to R+5.

Thanks to its lightness, it can even be used for construction in difficult terrain.

Building time in LSF

The Light Steel Framing model allows a quick and agile adaptation of the different jobs on the construction site. The construction time is thus reduced, making it less expensive than a traditional building site.

It is estimated that the average time per LSF project is 2 months / 100m2 including the finishes (excluding basement).

Fast and economical, construction is not affected by weather conditions.

All structural elements are shaped and cut in the factory according to the architect’s plans. On the construction site, all that remains is to assemble them. We are gladly free of the usual hazards encountered on construction sites: delivery delays, bad weather…

Environment - sustainable construction

Light Steel framing offers “green building” energy efficiency:

- 100% recyclable steel structural element

- We use OSB panels produced with trees specially planted for this purpose, under sustainable management and in compliance with environmental standards.

- The LSF model offers the highest energy quality grade awarded by the EU (class A1+) according to the directive n° 2002/91/CE

Moreover, galvanized steel resists external aggressions (humid air or insects), it does not require toxic treatment (fungicide or insecticide).

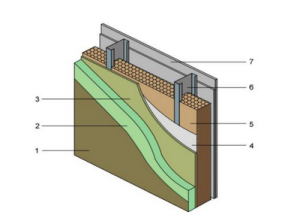

Finally, the perfectly hollow interior of the walls facilitates the passage of fluids and electrical conduits necessary for daily life. An excellent level of insulation is obtained thanks to its multi-layer structure which allows the elimination of thermal bridges (see diagram).

- Plaster or other coatings of your choice

- Peripheral insulation Swisspor type

- MgO plate, magnesium oxide, fireproof (12mm)

- Boltherm , iso. thermo acoustic, double aluminium blade

- Mineral wool insulation (120mm)

- Galvanized steel profile (Supporting structure)

- Two-layer plasterboard type KNAUF (2 X 12,5mm)

Construction quality

The LSF complies with the construction standards according to :

- The Swiss Society of Engineers and Architects (SIA)

- The International Organization for Standardization ISO

- The European Committee for Standardization

It allows a great agility of the solutions at the architectural level. The column-free and beamless design facilitates interior design and decoration. It allows for more spacious interiors.

Finally, this is the most resistant construction to earthquakes.

LSF projects by Orion

You may have guessed it, at Orion we are convinced of the importance of the innovations brought by the Light Steel framing. The model has already proved its worth in various emblematic projects that we have carried out, such as 3 villas (ON3X), to the great satisfaction of our clients!